OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

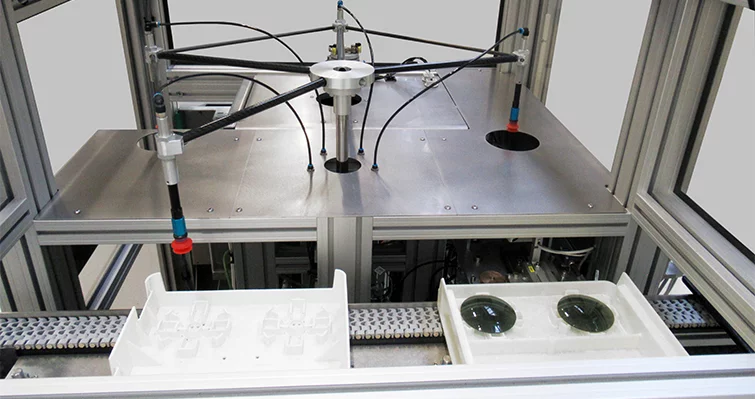

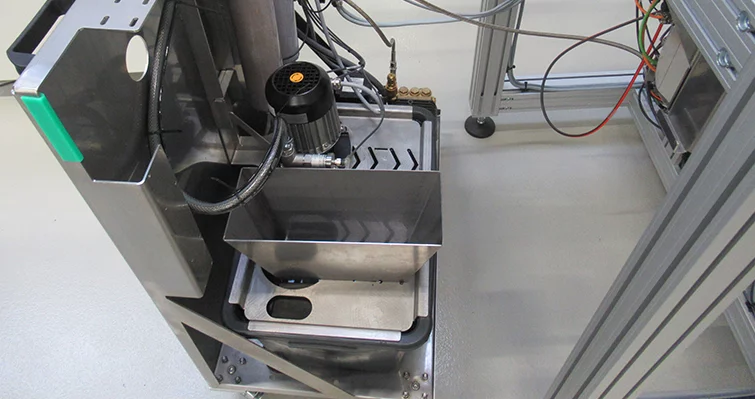

The automatic lens de-taper ODT 80 CNC-A is the ideal and flexible lens de-taper for small, midsize and big laboratories, using high pressure cold DI water technology.

Contact request

Sandusweg 2-4, 35435 Wettenberg, Deutschland