Service & Support

OptoTech Service Portfolio

Technology is our strength. Personal service our passion.

Our comprehensive service portfolio currently covers the following areas:

¬ Maintenance, Inspection, Service

¬ Processing Technology Support

¬ Individual Trainings and Workshops

¬ Machine Monitoring

¬ Remote Service

¬ Consumables

¬ Customized Machine Acceptance

¬ Software Extension

¬ Operational Command

¬ Procurement of Spare Parts

¬ Field Service Management

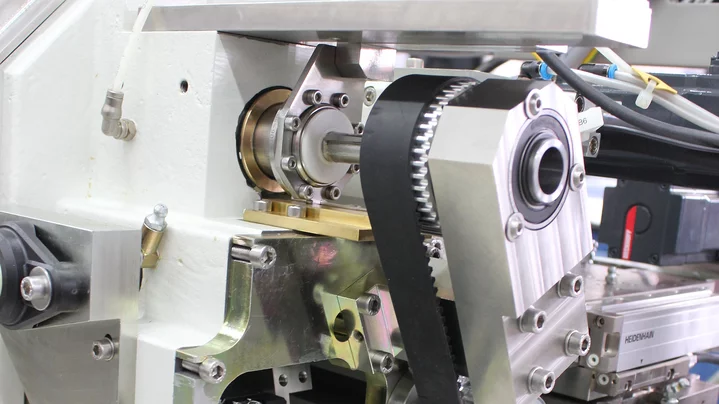

¬ Retrofitting

Service is Our Passion

Whether it's a trouble shooting, commissioning and training, technical questions or the supply of spare parts: our expert service team will be happy to support you. Together, we develop customized solutions and create individual service packages that are based on the requirements and needs of your production. Our global service network is consistently expanding, so that we can guarantee you fast response times in all areas also in the future.

Our Strengths. Your Benefits.

- International and highly qualified team of experienced employees

- Constantly growing service team worldwide to expand the global service network

- Fast response time in all areas

- Personal contact and flexible handling of customer needs

- Central service teams for all service questions

In order to improve our service quality and to be able to offer you attractive service solutions in the future, we are currently working on several projects

- Webshop

- Digital Spare Parts Catalogue

- Ticketing

Benefit from Our Know-How

We develop special training programs for our customers and offer them training on machine operation as well as various other workshops. On request, we conduct customer-specific training courses at one of our locations, remotely or at your site. Contact to us to find out more!

Spare Parts, Reparis & Returns

Speed and availability are also top priorities in our "Spare Parts & Repair" area. Therefore, 80% of all spare and wear parts are n stock in our headquarters in Germany, to guarantee you a reliable supply of spare parts and to avoid longer downtimes in your production .

Do you have questions about spare parts, repairs & returns? Contact us! We're here to help.

Evaluation of Your Coating Quality

Our Quality Test laboratory located in Magenta (Italy) offers a comprehensive coating analysis using a wide range of testing methods and equipment. All relevant properties on your ophthalmic lens are measured, inspected, and evaluated by our coating experts and are documented in an in-depth analysis report. This enables you to identify and eliminate possible quality defects or errors in your production process and overall optimize the coating result.

Our testing methods include thermal shock, reflection, water resistance, durability, sunlight aging, Bayer-Test and many other tests.