OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

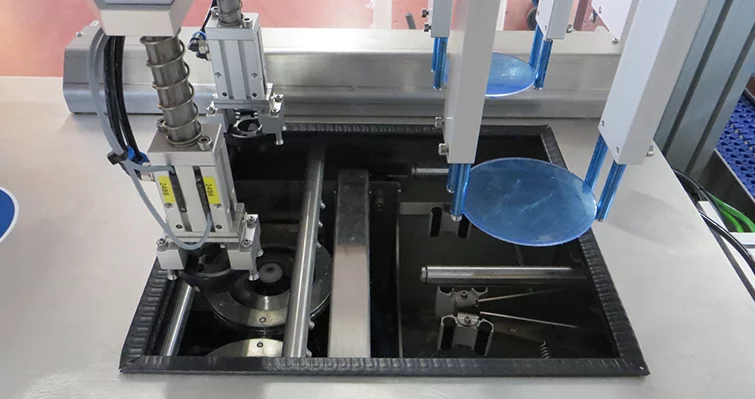

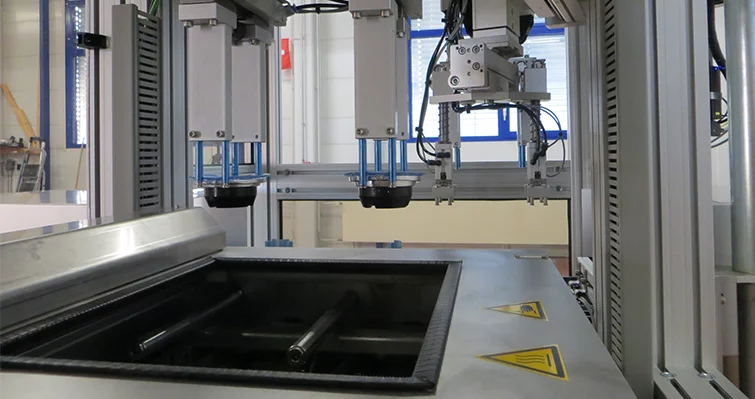

The OptoTech auto de-blocker ODB 80 Twin-A is designed for professional fully automated alloy deblocking. The machine allows uninterrupted de-blocking with no downtime.

Contact request

Sandusweg 2-4, 35435 Wettenberg, Deutschland