OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

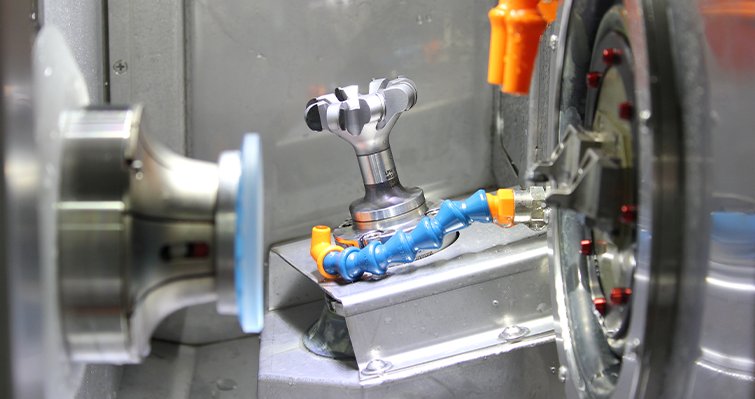

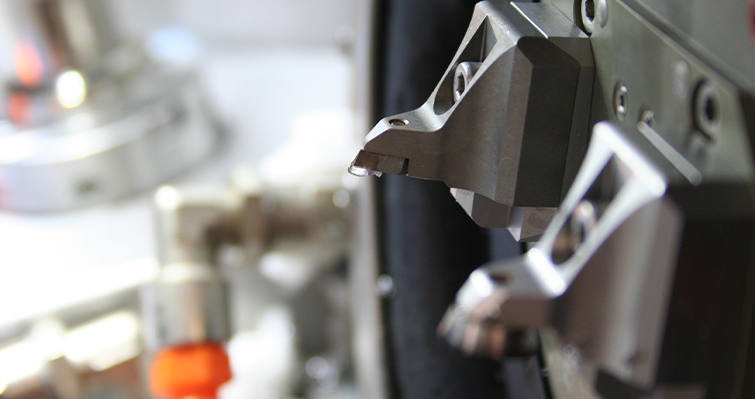

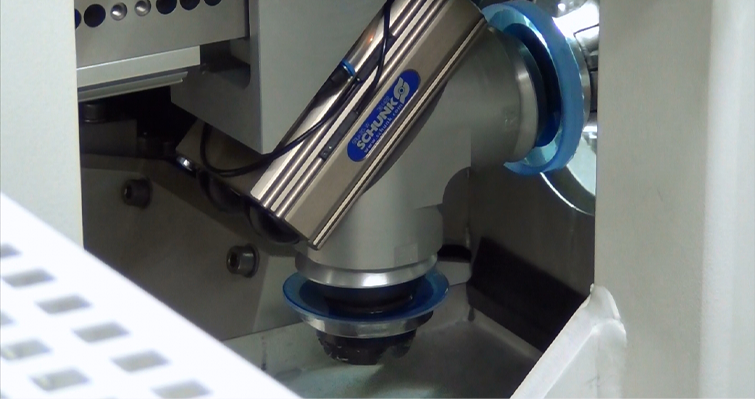

The FLASH-A Plus is an automated enhancement of our tried and tested FLASH series. Considerably increased speed of the tool spindle, combined with a high precision ball bearing, leads to significant improvements in quality and quantity. The combination of an ultrafast tool spindle and a high-performance controller make the FLASH-A Plus one of the most efficient digital surfacing machines on the market.

Contact request

Sandusweg 2-4, 35435 Wettenberg, Deutschland