OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

[email protected]

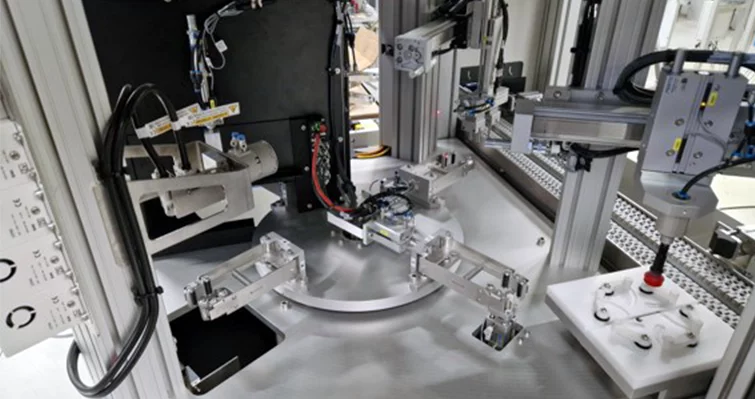

The VISTA is especially designed for detecting and localizing defects on ophthalmic lenses. Detects a comprehensive range of different defect categories. Big Data collection integrated.

Contact request

Sandusweg 2-4, 35435 Wettenberg, Deutschland