OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

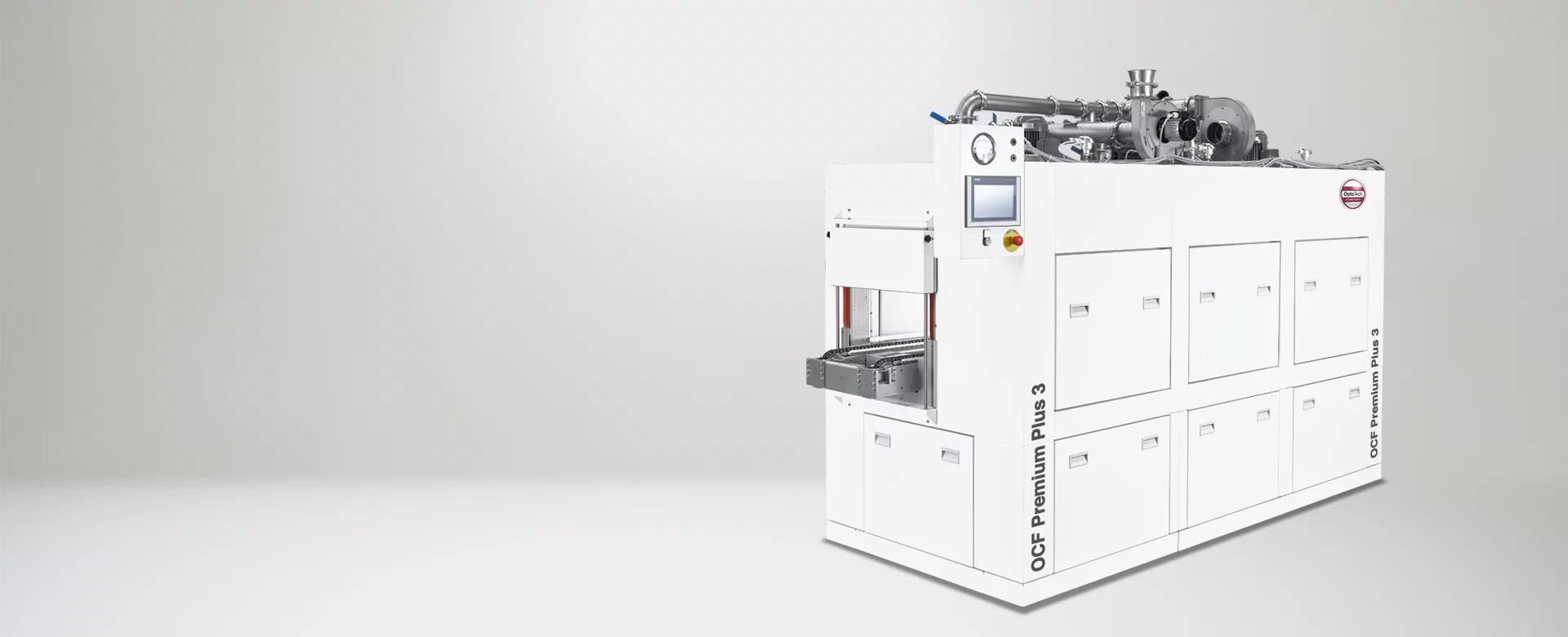

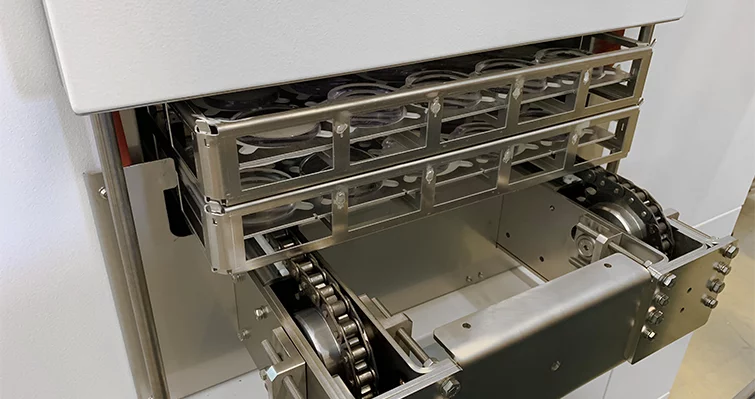

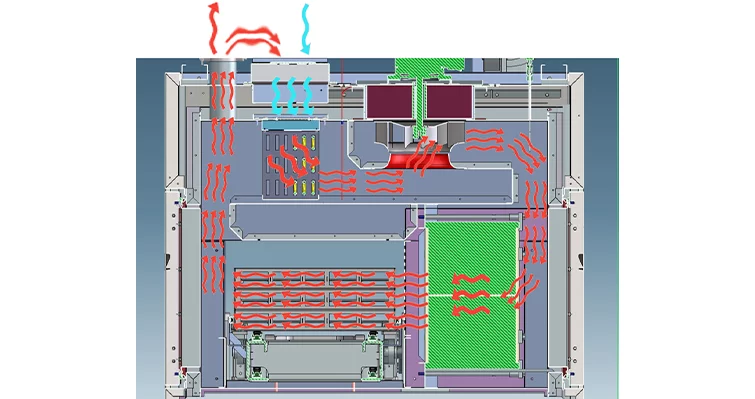

The OCF Premium Plus 3 is especially designed for curing coatings on ophthalmic lenses in a continuous cleanroom conveyor furnace after the hardcoating process. The modular system has 3 individually controlled heating zones whose working temperature can be set independently of each other offering maximum process flexibility.

Contact request

Controller and Software:

Sandusweg 2-4, 35435 Wettenberg, Deutschland