OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

OptoTech 2 Side lens processing consists of the following production steps:

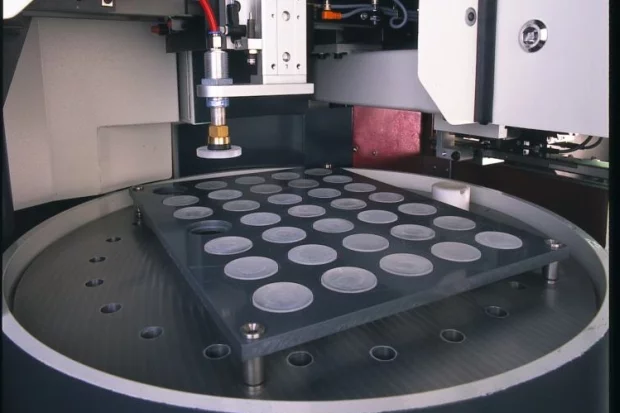

A magazine stores the raw lenses, generally moulds, the generator is doing the complete geometric processing. Subsequently the polishable lenses will be deposited back in the magazine.

Fully Automatic Loading Unit

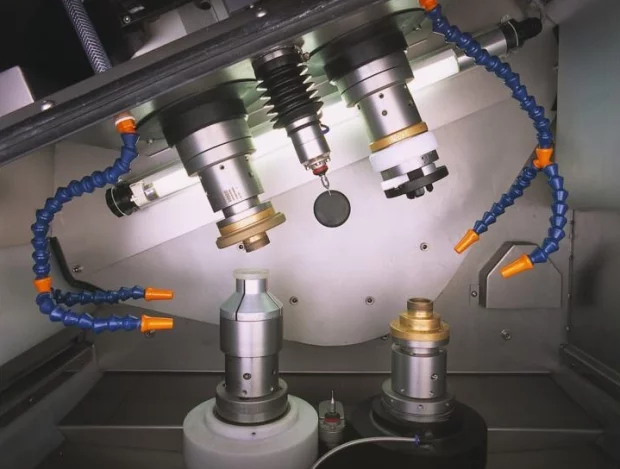

This technology is grounded on generators with 4 spindles that are equipped with our OptoTech CombiTools. These are tools that combine pre- and fine grinding tool with an integrated centering function. So the first spindle pair of the generator can process the first lens surface, the second spindle pair can process the second surface in inverse arrangement. Depending on the lens geometry the edge processing can be done on the first or the second lens side. Due to this the time and effort for the following centering on a seperate centering machine can be minimized. Partially the whole centering process can be omitted.

Work room of a generator for 2 side processing

The 2 side processing technique for grinding lenses suggests to adapt this concept to a polishing machine, too. Here you can also completely polish the lenses with CombiTools in inverse arrangement on both sides.

With this concept, consisting of one generator and one polisher, each equipped with technology for 2 side processing, producing lenses in big batch sizes is possible. The production line is fully automated and has all characteristics of a high speed production line, like grinding with ring tools, polishing with foil tools, etc.

Sandusweg 2-4, 35435 Wettenberg, Deutschland