OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

High performance at highest precision - The OptoTech WHEEL Technology

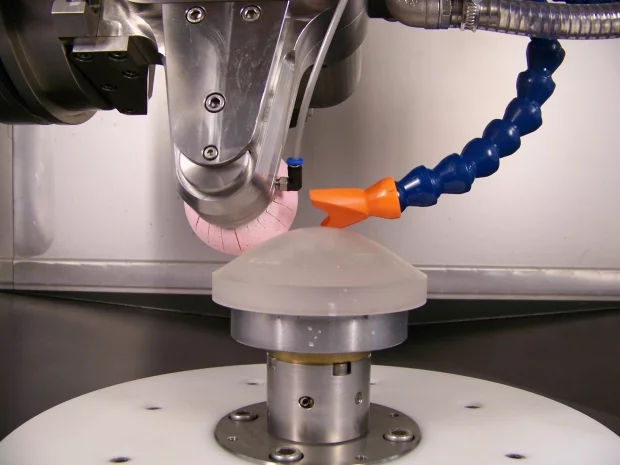

At the very heart of each OptoTech 5-Axis Polishing Machine of the MCP-Series is the WHEEL Technology.

The wheel is dressed and thus adjusted right in the machine. The stock removal rate and the size of the spot are variable. Due to a very small spot and the high-precision axe guides, very accurate corrections are possible. On the other hand, stock removals of several μm in one work step are not a problem either. This plays a huge role in todays asphere production. In order to avoid interfering mid-frequencies, a pre-polished sphere can be repolished to form the asphere, which to date has been a very time-consuming affair, or not even possible at the desired precision.

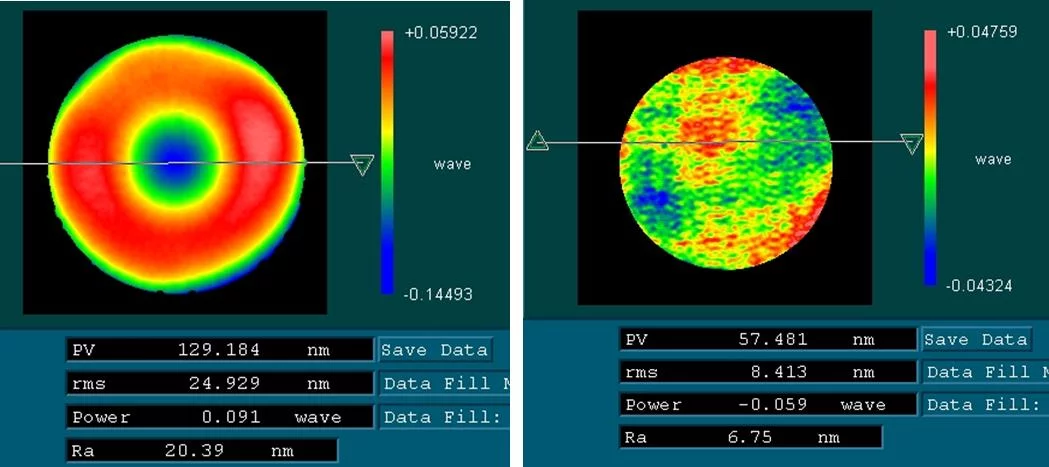

Sphere before and after correction with WHEEL technology

Your Benefits at a Glance:

Sandusweg 2-4, 35435 Wettenberg, Deutschland