OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

The challenge of polishing the second side of a lens is the possible damage of the already polished first side. That often happens when using a traditional membrane chuck.

There is a way to by-pass this problem by placing protective paint on the polished side. That necessiates to take the lens out of the process chain, painting and drying it in an additional step before processing the second side. It is easy to see, that this is opposed to the aspired linkage of generators and polishing machines.

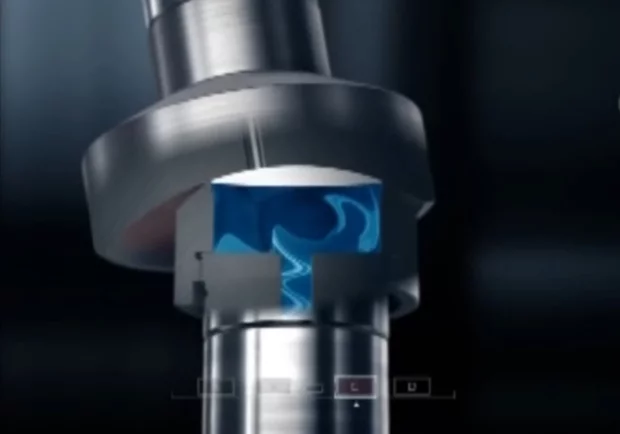

The solution for this problem is our HydroSpeed® Polishing Technology. Using this technology, the lens is pushed against the polishing tool by the polishing fluid that is pumped through the chuck. To do so, the polishing fluid unit is equipped with an additional high-pressure pump that pumps polishing fluid through the lower spindle. As a result the lens "sits" on the fluid and is guided all around.

HydroSpeed® has the following advantages:

That means:

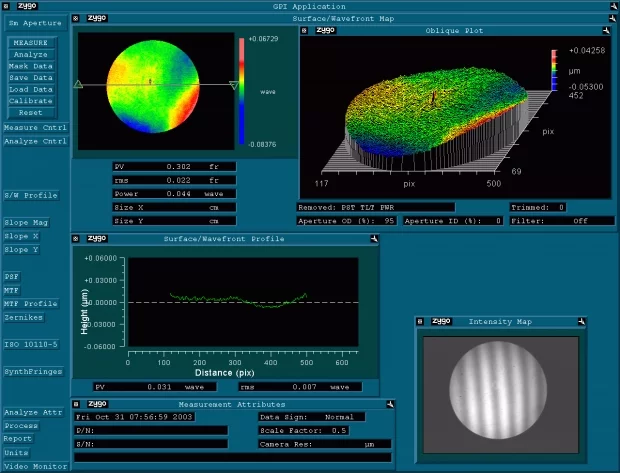

Interferogram of a HydroSpeed® polished lens

An production cell with this technology was first introduced by OptoTech at the OPTATEC 2002. The production cell only consists of one generator and one polishing machine with the following production steps:

HydroSpeed® Polishing has especially been developed for large scale production, but can also show its advantages at lower scales. Due to the fact that no special membrane chuck is needed, the complexity of the tool production is considerably lower.

Sandusweg 2-4, 35435 Wettenberg, Deutschland