OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

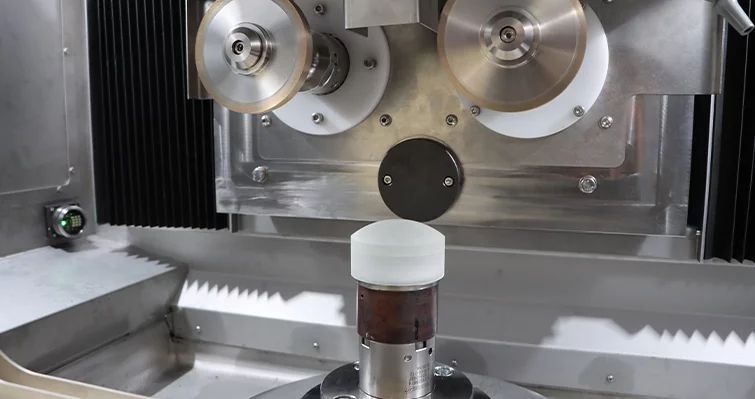

The UPG 80 CNC-2C is ideal for fine and ultra-precision grinding of optical surfaces and brittle-hard materials. With minimal subsurface damage, it significantly reduces polishing effort and time while ensuring excellent form accuracy. Precise axis guidance, a vibration-dampened design, and high-quality spindle bearings guarantee outstanding surface form and quality. Typical applications include semiconductor, SiC processing, aerospace, laser optics, and precision optics.

Contact request

Sandusweg 2-4, 35435 Wettenberg, Deutschland