OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

[email protected]

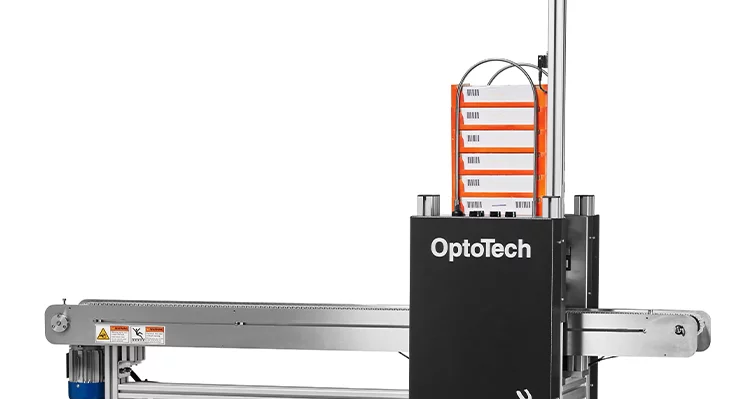

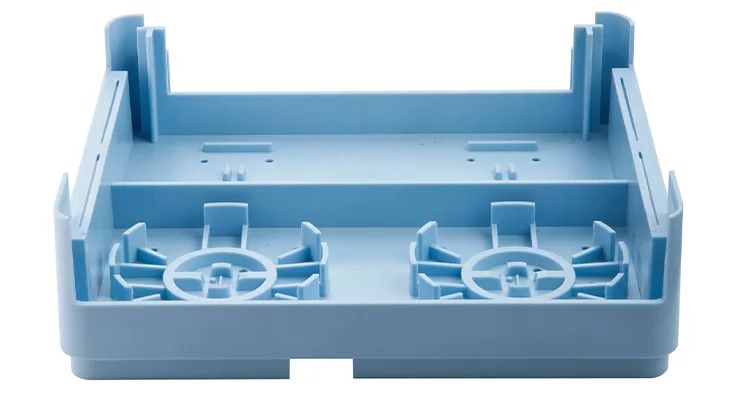

Simple but effective jobtray stacking and de-stacking unit including driven conveyor, clamping unit, sensors, separator and independent control (no connection to IQ-Control necessary)

Contact request

Sandusweg 2-4, 35435 Wettenberg, Deutschland