OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

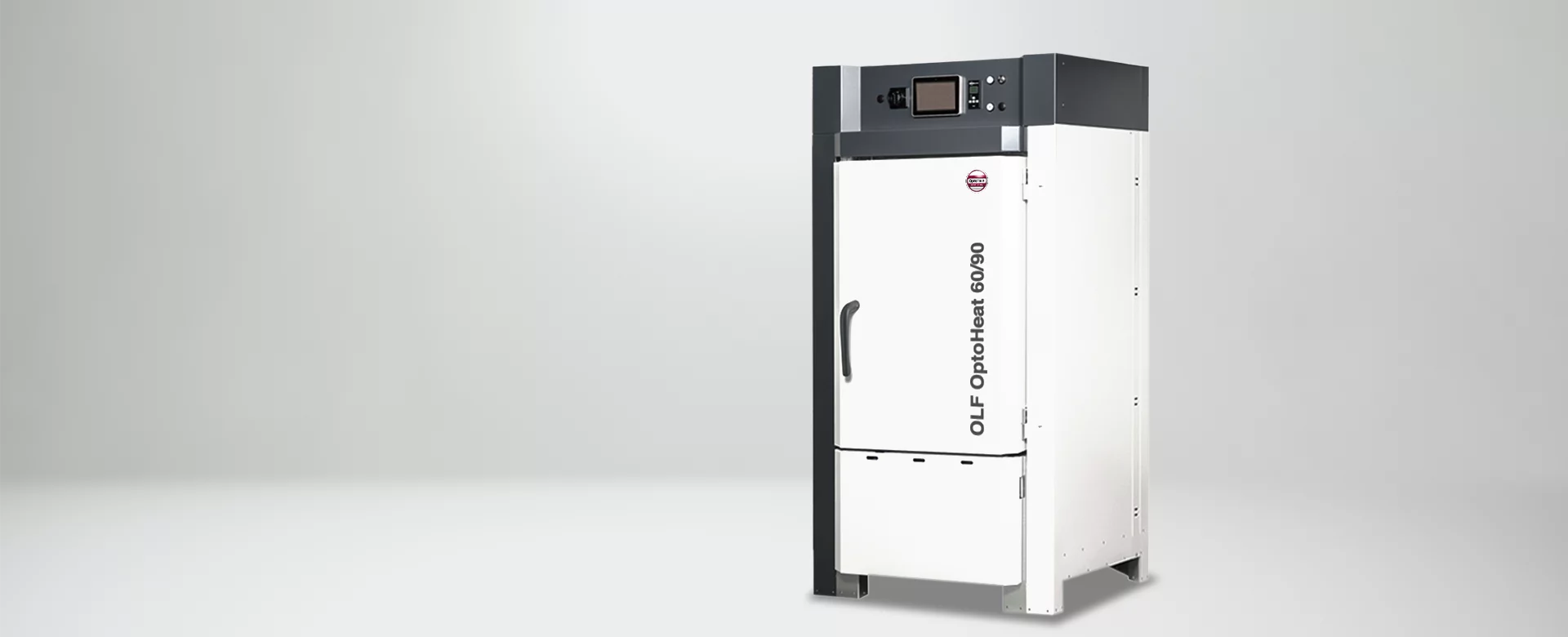

The OLF OptoHeat furnaces are specially designed for curing coatings on ophthalmic lenses after the hardcoating process. The system is available in 2 different versions, making it suitable for labs of any size.

Contact request

Sandusweg 2-4, 35435 Wettenberg, Deutschland