OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

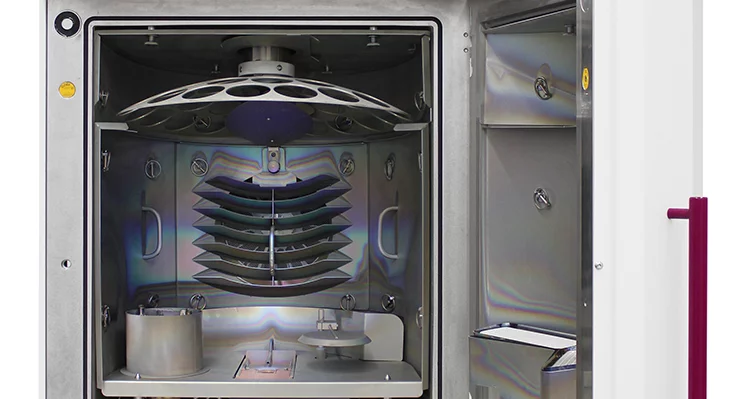

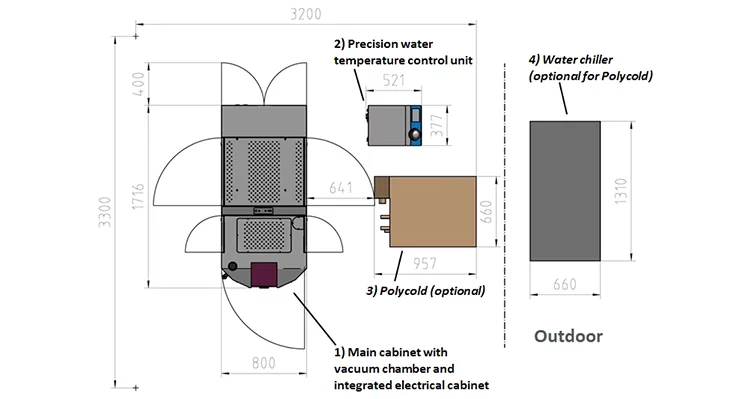

The OptoTech OAC-60 evaporation coater is used for the application of high quality coatings like anti-reflective (AR) coatings and clean coats (CC) on ophthalmic lenses. It is the ideal coating unit for low volume and flexible lens production. The OAC coating system is characterized by the product quality for which OptoTech is known, ease of use, and exceptional reliability in the daily production operation.

Contact request

DURACOTE - AR coating on plastic lenses

DURAFLEX - Mirror coating in different vibrant colours

DURAQUARTZ - AR coating on mineral lenses

IRIDIO - Anti-static coating

IR PROTECT - IR protection with NIR blocker

RELAX - Blue light protection filter

UV - UV light protection filter

Tinted AR - Tinted lenses in grey or brown (solid)

Sandusweg 2-4, 35435 Wettenberg, Deutschland