OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

info.de@optotech.net

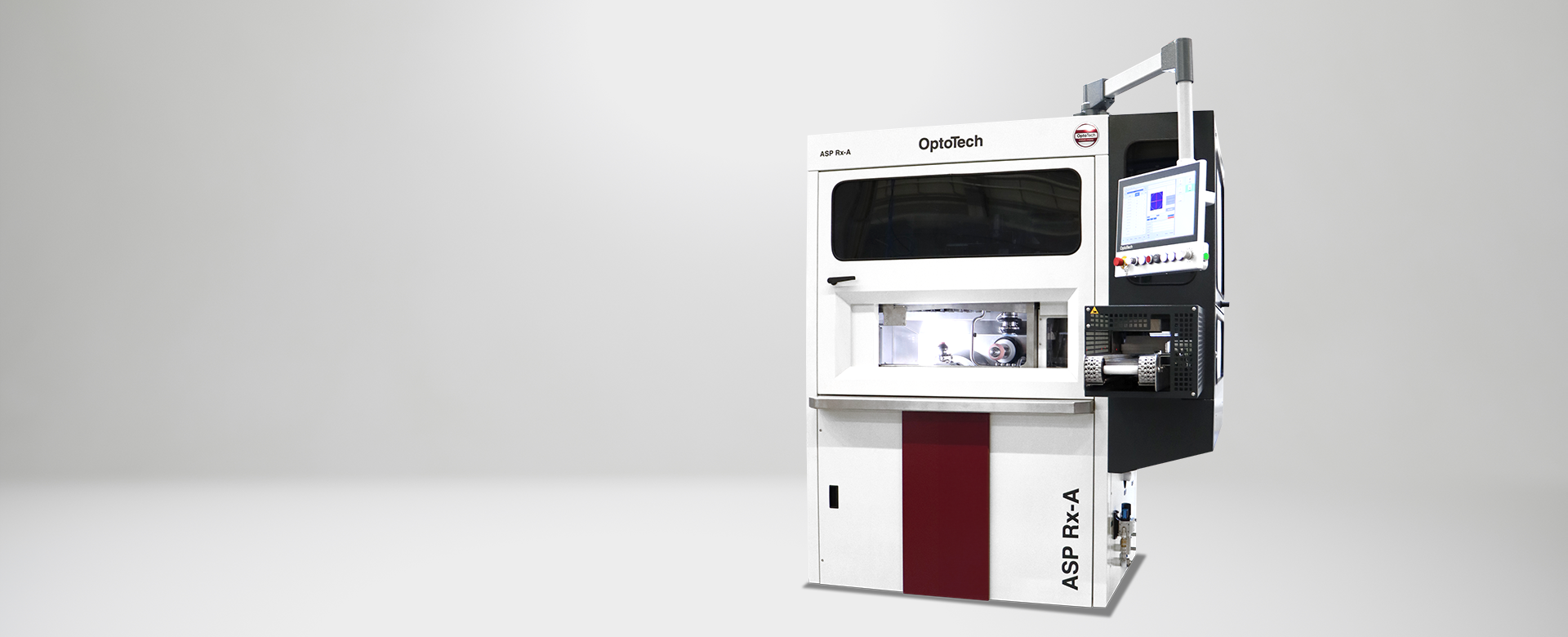

The OptoTech Digital-Surfacing-Polisher ASP Rx-A is designed for full automatic high speed polishing of one toric/atoric or backside progressive mineral lens. Round, oval, or lenses of any other shape can be polished.

Contact request

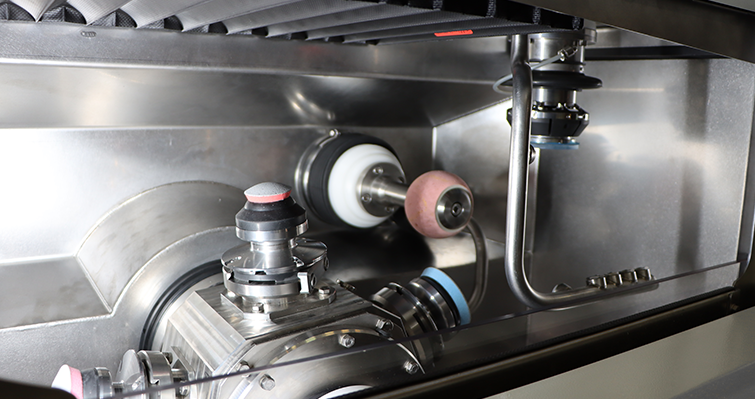

The machine consists of two machining stations:

Sandusweg 2-4, 35435 Wettenberg, Deutschland