OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

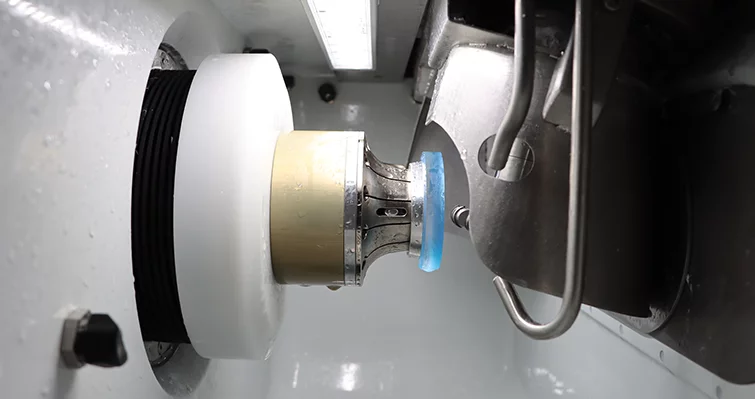

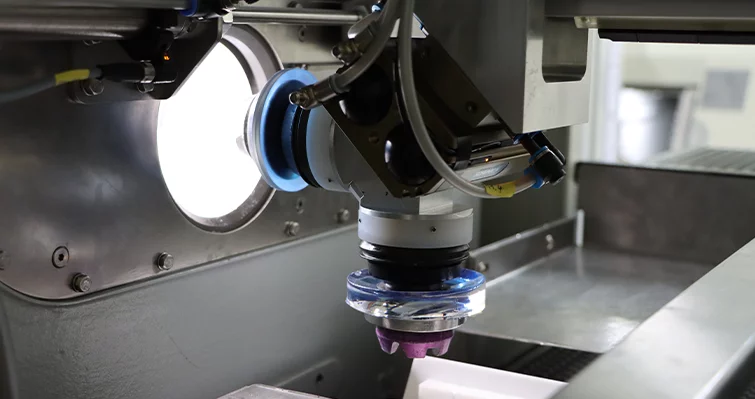

The Rx-lens production of the future will significantly change all operations and processes. As an entry-level concept for automatic Rx production 2.0, OptoTech developed the new SWARFMASTER for high-performance pre-grinding of mineral and organic lenses (toric and freeform). By separating the pre- and fine grinding processes, you optimize your production and ultimately increase the performance and quality of your surfacing machines for mineral lenses and glass molds as well as organic lenses.

Contact request

Application area: mineral lenses, glass molds and organic lenses. Backside progressives; Atorical; Individual; Front progressive; Standard toric; Blended lenses

Sandusweg 2-4, 35435 Wettenberg, Deutschland