OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

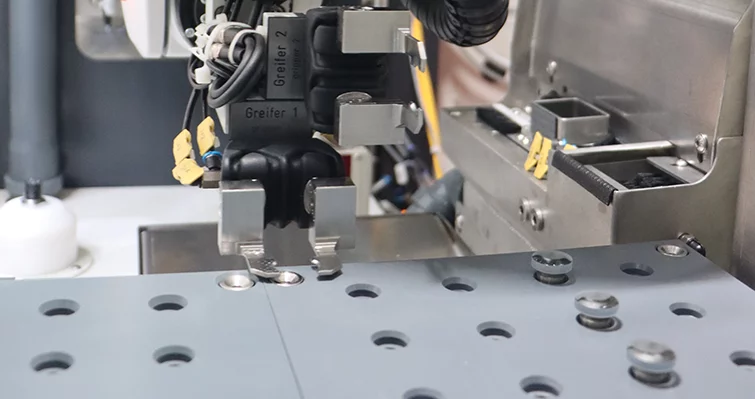

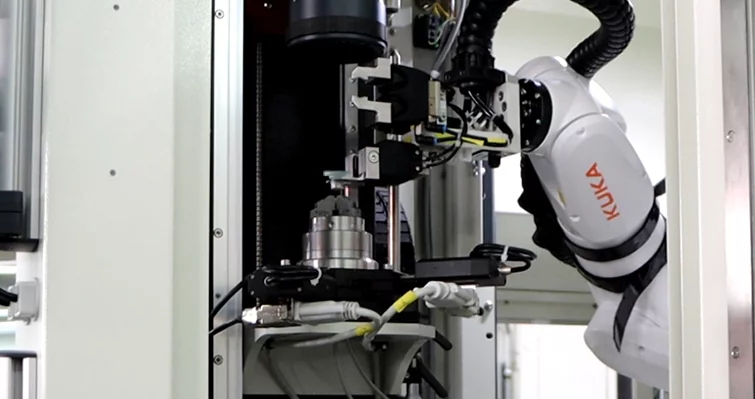

The RPL 80 is the high performance robot solution from OptoTech, that allows automatic loading and unloading of the SM 80 CNC-TC generator, the SPK 80 CNC polisher as well as the OWI 60 HP Invers-A interferometer. The RPL 80 can handle single surfaces (up to Ø80mm) as well as lenses on cementing pieces.

Contact request

Range of Functions:

1. Pick up of the lens from the DIN pallets or transport belt

2. Handling of lenses on cementing pieces or single surfaces

3. RFID reading and writing device option (RFID integrated in cementing piece)

4. Pre-centering of the lens before insertion in the machine via integrated precentering station (option)

5. Pick up of the processed lens from the working room of the machine or interferometer and insertion of the new lens

6. If necessary, cleaning of the lens in the integrated cleaning station with water and air, in the second cleaning station with a sponge and cloth or surfactant basin as well as a gripper cleaning station are all available as an option

7. DS 100-A digital spherometer (option) for fast and simple radii measurement of spherical lenses

8. Return of the processed lens to the pallet or the transport belt

Sandusweg 2-4, 35435 Wettenberg, Deutschland