OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

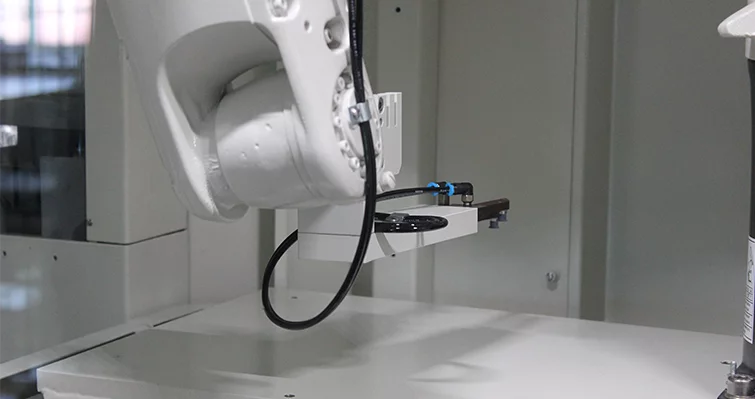

The RPL 30 is the high performance robot solution from OptoTech, that allows automatic loading and unloading of the SM 30 CNC generator and the SPO 30 CNC polisher. The RPL 30 can handle single surfaces (up to Ø20mm) as well as lenses on cementing pieces.

Contact request

Range of Functions:

1. Pick up of the lens from the lens storage (DIN pallet)

2. Handling of up to 2 lenses via double suction cups

3. Pre-centering of the lens before insertion in the machine via integrated precentering station

4. Pick up of the processed lens from the working area of the machine and insertion of the new lens

5. If necessary, cleaning of the lens in the integrated cleaning station with water and air (option)

6. If necessary, transfering lenses via transfer drawers (option) for measuring withouth interrupting the robot cycle

7. Storage of processed lenses in dip tank (option)

8. Opening and closing drawers (option) in the lens storage

Sandusweg 2-4, 35435 Wettenberg, Deutschland