OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

[email protected]

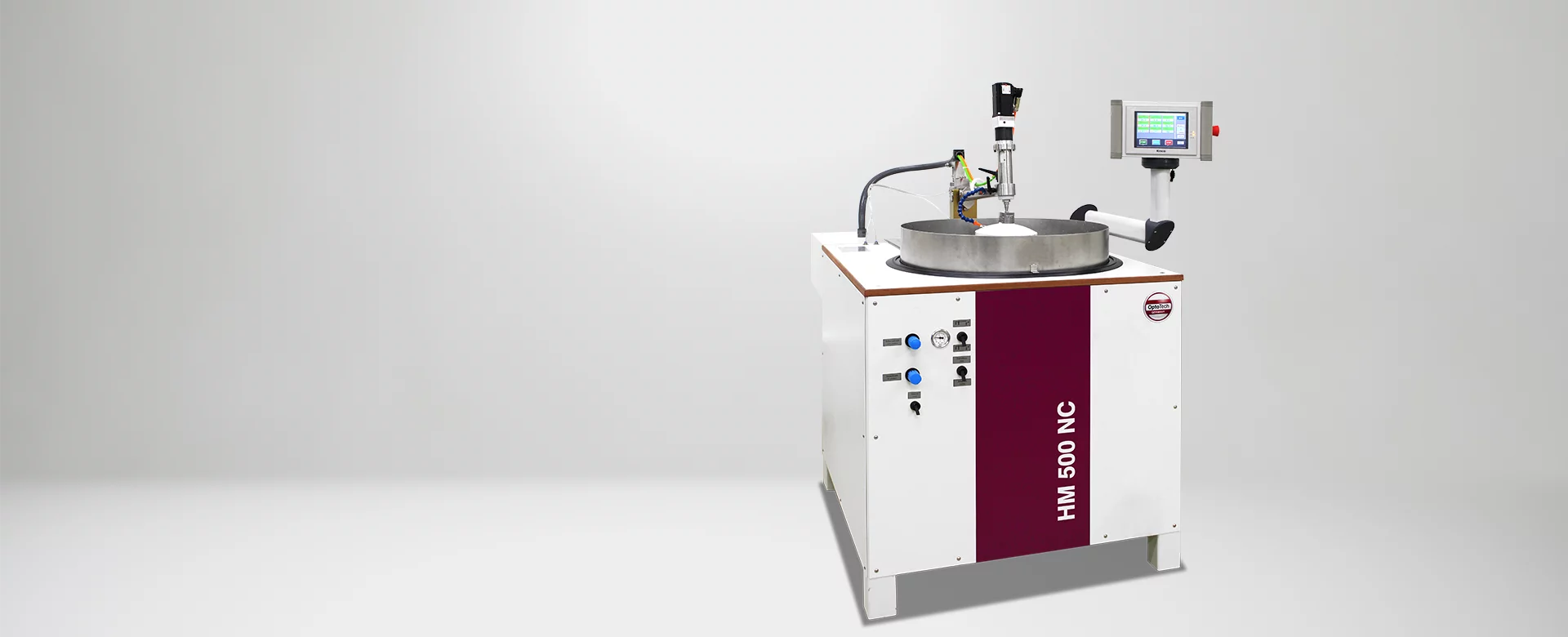

The HM 500 NC is one of the worldwide first NC controlled polishing machines in conventional technology. Due to the simple NC controller it is possible to save parameters as well as the program kinematics. The HM 500 NC is a true high-end tool for the production of high class optics in small series and special optics.

Contact request

Sandusweg 2-4, 35435 Wettenberg, Deutschland